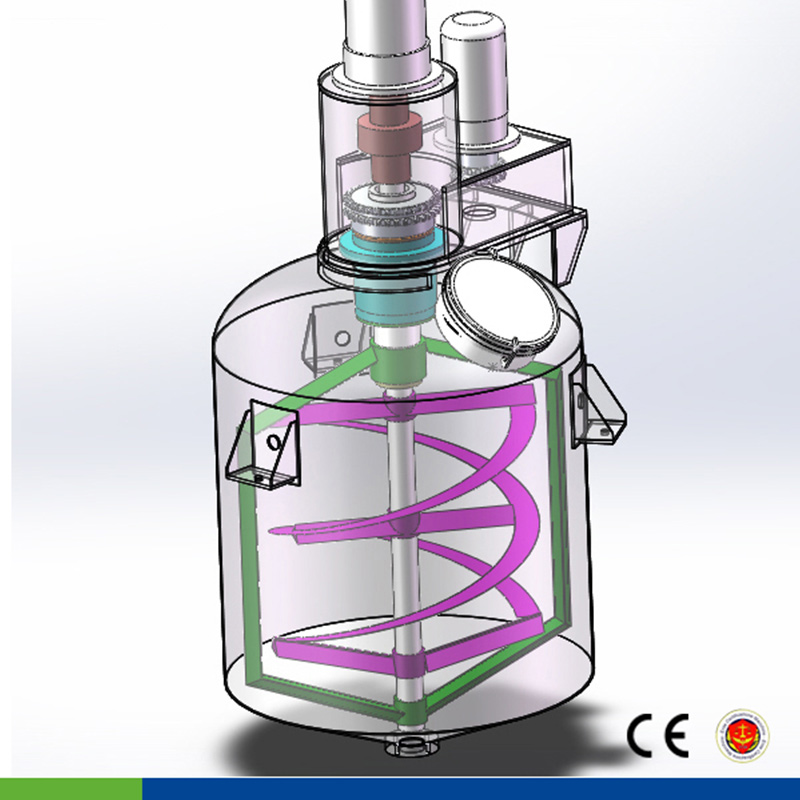

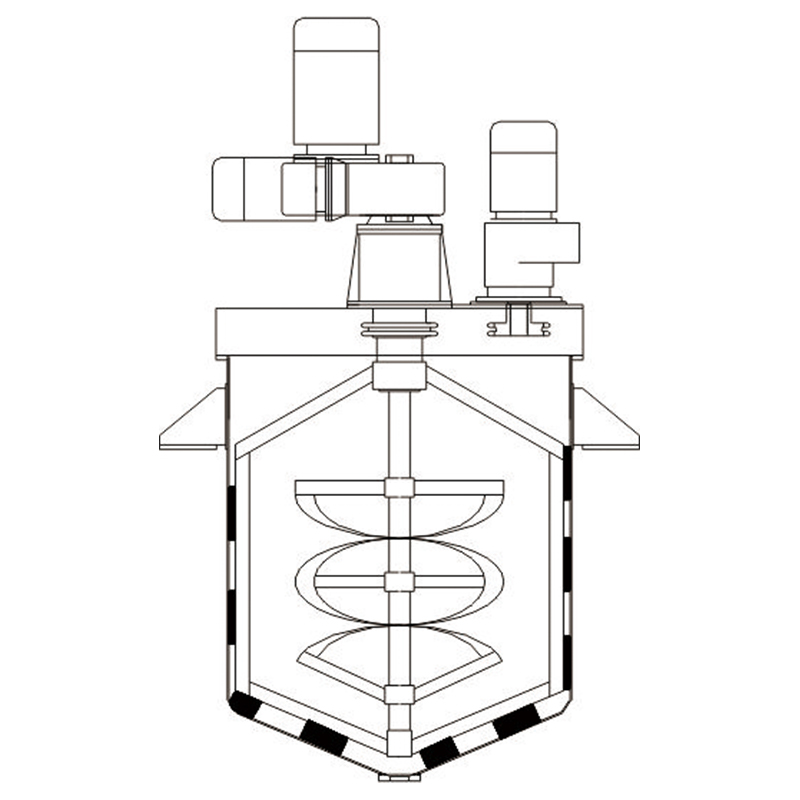

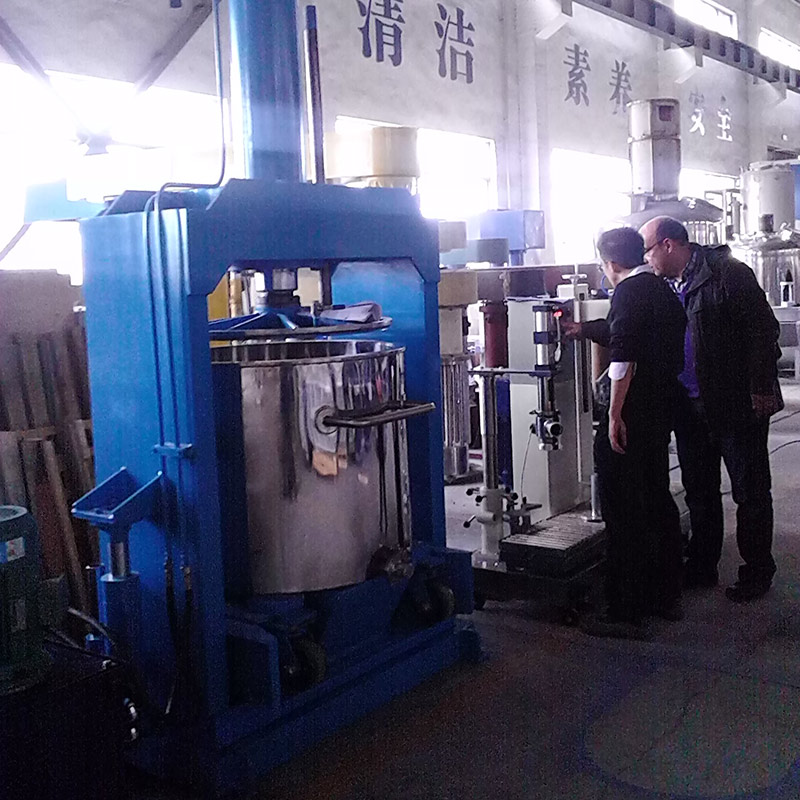

CE approved cosmetic cream blending machine for body lotion homogenizersProduct ShotsLifting type vacuum emulsifier mixer homogenizer with oil and water potsSS316L mixing system with PTFE scraper-Mixing speed is 0-60rpm, it can be adjusted with inverter.Oil and water phase boilers -Dispersion blending speed can be up to 1440rpmFeatures1. Vacuum defoaming function can make the materials meet the requirement of being aseptic.2. The main boiler lid adopts the lifting system, it is easy to clean and the cleaning effect is more obvious, the main boileradopts a tilting discharge.3. The main tank can be heated and cooled with an electric heating function.4. Adopts imported electric appliances which can meet international standards.5. Contacted parts are made of SS316LWall scraper mixerHomogenizerWater and oil potDisperser50L1.1kw, 0-65rpm2.2kw, 0-3600rpm45/30L0.37/0.37kw, 1440rpm100L1.5kw, 0-65rpm4kw, 0-3600rpm90/60L0.55/0.55kw, 1440rpm200L3kw, 0-65rpm5.5kw, 0-3600rpm180/120L0.75/0.75kw, 1440rpm300L4kw, 0-65rpm7.5kw, 0-3600rpm270/180L1.1/1.1kw, 1440rpm500L5.5kw, 0-65rpm11kw, 0-3600rpm450/300L1.5/1.5kw, 1440rpmApplicationWhat can we do?We can provide you with excellent production lines and packing solutions, pl; 2. Your produ ProfileFAQ1. Can you customize the volume for the vacuum emulsifier?Yes, we can do it. But it will take much more time to customize it. The production time for standard machine is about 30 working days.2. Which parts can you customize?Such as mixer/homogenizer motor, mixing paddle, layer, heating method, control type(PLC/Button), electric box, volume, etc. It depends on your requirements.3. What functions does the machine have?Such as vacuum defoaming, heating, cooling, mixing, emulsifying, high shear homogenizing, lifting, auto discharge, auto cleaning,etc.4. What products can this machine produce?Cosmetics: face cream, lotion, serum, body butter, liquid foundation, sunscreen cream, od: mayonnaise, ketchup, source, etc.Daily chemical: shampoo, conditioner, hair essential oil, toothpaste, liquid soap, detergent, etc.5. What is the function of oil/water tank?Good question! Its function is pre-heating/pre-process. The semi-finished products will be transferred to the main tank formixing. If you want to buy vacuum emulsifier with small volume, so we don't rmend you to equip them.6. What is the brand for the motor of vacuum emulsifier?Normally we use the Siemens Motor, sometimes it's difficult to order the Siemens motor, so our client will also choose ABB motor.7. Can you also customize the power supply?Yes, that's no problem. The standard power supply for the vacuum emulsifier is 3P/380V, we can customize the voltage based on your requirements. Such as 3P/220V, 1P/220V, 1P/110V, 3P/415V, etc. To be told, the production time will be longer if we customize it.8. Please let me know the material used, ok?The contacted part is made of SS316L, and the machine body is made of SUS304.9. I am a starter in the cosmetic field, and I want to rent a factory to start it, what suggestions will you provide us?For starters, we rmend that you can choose 50L or 100L small vacuum emulsifier, semi-auto filling machine, and capping machine. When your business be bigger, you can buy the automatic machine. Anyway, please let me know your specific requirements, such per day. It will be better if you can let us know your budget.10. Can you let me know the speed for the motors?We equip the inverters, the speed of mixing motor is 0-63rpm, the speed of homogenizing motor is 0-3000rpm, which means the speed can be adjusted easily. BwLfTJqdhHX2 mixing tank soap making machine price Vacuum homogenizer for making body cream lotion, face ceam, hand cream, cosmetics paste etcThe product is mainly applied in such industries as daily chemical care products, biopharmaceutical industry, food industry, paint and ink, ometer materials, petrochemical industry, printing and dyeing auxiliaries, pulp & paper, pesticide, fertilier, plastic & rubber, electrics and electronics, fine chemical industry, etc. The emulsifying effect is more prominent for materials of high base viscosity and high solid ap making machine price, mixing tankFeatures:plex scraping board blending oar is suitable to every kind ofplicated recipe and achieve optimizing effect;2. Polytetrafluroethylene scraping board cater to body of blending groove and scrape out viscosity material on boiler waease motor power more thoroughly and strongly. During fewproduction, it can exert homogenizing effect fully;4.Mightiness balance isotactic curve rotor is matched with stator with corresponding structure to realize liquid high -capability cut,rubbing,centrifugal to make sure exquisite and slick cream; boiler body and pipe surface mirror polishing 300EMSH (sanitation grade) accords with Daily Chemical and GMP regulation.5.Homogenizing vacuum emulsifier mixer can choose frequency conversion timing homogenizer and highest rotate speed is 4500 r/minModelEffectiveEmulsifying MotorAgitatorVacuum pumpelect/LKWRPMKWRPMKWLimit VacuumSME-5.160.2SME-10.160.2SME-20.190.2SME.1120.2SME.5-0.1240.2SME-200L.2-0.1280.2SME-300L.1320.2SME.1500.2SME-.1540.2SME-2000L20.5-0.1rmend steam hetaing0.2SME-5000L50.10.2The parameters for reference ONLY, all the machines can be customized ter-sales Service1.Warranty time: one year, from the date which the product is qualified y damage except the wrong operation during warranty period is repaired freely.But the travel and hotel expenses should be count on buyer.2. Commissioning services: the product's installation andmissioning at the demand side, our engineers will not leave there until get your agreement.3. Training services: our engineers will train your staff to operate it during the period of installation andmissioning,and they will not leave there until your staff can operate it properly and normally.4. Maintece services: any malfunction happened, once you inquiry us, we will reply you within 48 hours except the special reasons.5. Lifelong services: we provide lifelong services for all the products we sold out, and supply the spare parts with discount price.6. Certificate services: we can provide related certificates to customers freely according to the request of customers.7. Inspectio or your inspector to inspect the products before shipment.8. The file: the Manual Specification, report of the material which used to the equipment and other documents related to the GMP authentication information will be provided by us.RFQQ: Are you a factory?A: Yes we are a factory with more than 20 years manufacturing experience. One is in Jiangsu,Another is in next to our office.Q:I'm new in our industry,but I'm planing to set up a factory, what can I do?A: We will design the most suitable proposal based on your actual situation, such as the daily production,raw material formula, factory layout, etc. Also we would like to intro- duce some excellent suppliers of raw materials, bottles,labels, etc if needed. After sales, engineer will be send to fields installation, training andmissioning.Q:Are your machines difficult to operate? How do you teach us using the machine?A: Our machines are fool-style operation design,very easy to sides,before delivery we will shoot instruction video to introduce machines'functions and to teach you how to use them. xff1Jptbfwik Cosmetic Cream Homogenizing Emulsifier Mixer Machine Liquid Paste Shampoo Body Butter Making MachineVacuum Mixer Homogenizer is a cudes self-contained vacuum system and heating system. Vacuum emulsifying machine is applicable for a wide variety of viscosity product, i.e.emulsions and semisolid. It integrates with pressure, heating, cooling and vacuum for Agitating, Mixing, Emulgating, Dispergating,Suspending, Homogenizing is flexible from 5L-5000L,just please tell us your products requirement, then we can rmend suitable model for you.Features :cuum emulsifying pot is designed withvacuum systemto pump the products of water and oil phase to main working pot , and remove bubbles during production process.2.Hydrualic lifting systemof emulsifier mixer pot is easilier to clean the scraper mixer blender and homogenizer mixer. more safe than pneumatic lifting .3.Electricheating systemcan heat or cool the jacket in different production process. Steam heating is option .direction blending and high shear homogenizerto ensure the emulsiyfing and mixing more evenly and effectively . It's the ideal cosmetics manufacturing equipment .is model with working plaftorm, more convenient for operating and observe production status.Application:This machine is suitable for the production of cosmetics, medicine, food, chemistry, dyeing, printing ink and other industrial products, especially for the material with high viscosity of matrix and high solid content of emulsifying more effective.(1) Cosmetics products: face cream, lotion, lipstick, shampoo, etc(2) Pharmaceutical industrial products: ointment, syrup, eye medicine, etc(3) Food industrial products: jam, butter, margarine, etc(4) Chemical industrial products: chemicals, synthetic adhesives, etc(5) Dyeing industrial products: pigments, titanium oxide, etc(6) Printing ink: color ink, resin ink, newspaper ink, etc(7) Others: pigments, waxes, coatings, etcProduct ParametersDescription200L Automatic Vacuum High Shear Cream Paste Emulsifying Homogenizer Mixer Machine High Speed Dispenser TankVoltageAC 380V/3phase, can be customizedMotorSiemens, ABB is optionalFrequency inverterDelta, MitsubishiMixing systemtop frame scraper mixer +bottom homogenizerMixing speedtop blending : 0-63rpmbottom homogenizer : 0-2880rpmVacuum mixer pot3 layers stainless steel , inner layer is SUS316LWater and oil pat3 layers stainless steel , inner layer is SUS316LProducts outletManual discharge or bottom directly dischargeDimension3050*3230*2100(2970)mmDetailed Photos200L hydraulic lifting vacuum emulsifying machine+electric tilting system50L model+PLC Profile TPxR52aXWQa0 Custom Made 50L- 10,000L, 20 Years Of Experience. Reasonable Price And Best Service, CE Certificated Products. Please contact us for the offer.Mixing tankse in various sizes and can be used in a wide range of industries.We are a manufacturer of stainless steel mixing tanks designed to fit your products and scription:This series is the most advanced blending equipment in fields of Chemical, pharmaceutical, food, etc. When the high-speed super-fine emulsification paddle works, it throws the materials in the center of rotor to stator at a high speed,then through tooth clearance of stator,and shearing,collision and crushing between rotor and stator,the super-fine emulsification is realized. therefore,it is an integrated equipmentprising functions such as blending,emulsifying,homogenizing,solving and crushing.We can customize according to your drawings, or we can pro&Characteristic of stainless steel mixing equipment* Contact part : SUS316L or SUS304* Function : heating, blending, homogenizing* Mixing system : frame scraper agitator mixer and high shear homogenizer mixer* Heating system : jacket heating / running water cooling* Movable design and simple to operateApplicable Products.1. Cosmetics industry: skin care cream, shaving cream, shampoo, toothpaste, cold cream, cold sun cream, facial cleanser, nutrition dense, detergent, shampoo, hair cream, conditioner, serum, moisturizing cream, Hand cream and so on.2. Daily chemical industry:Laundry liquid production, hand sanitizer, toilet net, car glass water.3. Pharmaceutical Industry:Latex, emulsion, ointment (ointment), oral syrup, oral liquid and the like.4. Food Industry:Sauces, cheese, nutritional liquid, baby food, chocolate, sugar and so on.5. Chemical Industry:Latex, Sauce, specified products, paints, coatings, resins, adhesives, lubricants and so nfiguration:1. Quick opening manhole.2. Various types of CIP cleaners.3. Sanitary ventilation hood to defend against flies insects.4. Adjustable triangular bracket.5. Detachable feeding tubes.6. Thermometer (According to the customer's requirements).7. Ladder (According to the customer's requirements).8. Advancing side blender9. Level meter and level controller (According to the customer's requirements).10. Anti-vortex andard mixing tanks or tailor-made for your product and processWe understand that every mixing tank is different. Therefor, we design our tanks tailor-made for you, so you can be sure that the tank will suiude into your tank are:* Tillable*Fully integrated control panel*Heated and/or cooled*Agitators*Load cells*Level switches*Cleaning options*Skid mountedFeatures:1. Inner tank body, jacket and outer layer, with thermal insulation material filled in between.2. Materials are all sanitary stainless steel.3. User-friendly design ,easy to operate.4. Transition area of interior wall on tank adopts arc for transition to ensure no deader of itator design and fabrication:In addition to tanks, We also make its own agitators. This way you have one point of contact for the entire tank concept. Agitators that we design and produce are:*Gate agitator*Anchor agitator*Scraping agitator*Propeller agitator*Bottom driven agitator*Dispersing disk*Rotor/stator*Screw agitator*Combination of agitators*High shear mixer*Turbo mixer*Side entry agitator*Static mixer*External homogenizerStirrer Inside The Tank We Have Different Types: Homogenizer, Paddle, Frame, Propeller, Anchor With Scraper ( Other Stirrer can be customized )1, Bottom magnetic agitator with propeller impeller, speed fromrpm orrpm. This kind of agitator is mixing thin viscosity, such as eye drop, injection, CIP liquid, water, etc.2, Top mechanical agitator with propeller impeller, speed at fix 71rpm or adjustablerpm or special requirement. This kind of agitator is mixing syrup, injection, blood, oral liquid, culture media, etc.3, Top mechanical agitator with anchor or frame impeller, speed is fromrpm. It is mixing higher viscosity, such as sediment or viscosity oral liquid, etc.4, Top emulsification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. This kind of agitator is mixing most high viscosity, such as suspension, oil, fat emulsification, etc.5, Bottom emulsification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. This kind of agitator is mixing most high viscosity, such as suspension, oil, fat emulsification, etc.We have more than one hundred different types of mixers to meet your product process.Application:1. Cosmeticand daily chemical product:Cosmetic cream, lotion, shampoo, detergent, health care product, gel, Laundry detergent, hand sanitizer, armpits lotion etc.2. Pharmaceuticalproduct:Ointment, Ice packs, injection liquid, penicillin etc.3. Food:Salad, mayonnaise, peanut butter, sesame butter, buttery, Animal fat, iced products, healthy food verage:Fruit Juice, Milk Juice etc.5. Chemical:Paints, Pigments, dyes, photo solvents, Rubber and resin, pesticides, Shoe polish, general chemicals tailed PhotosCertificationsPackaging & ShippingWe are experienced in the whole packing and shipping process,and we will be responsible for any damage made during shipping and send clients replacements for free.* Suffuding bubble bag, foam board and others.* Qualified wooden package or carton for different products or as customer require* Strict packing process to ensure the safety andpleteness of the goodsFAQQ1. What is your terms of packing?A: Generally, we pack our goods in a plywood case or carton package for small parts.If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.Q2. What are your terms of payment?A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.We'll show you the photos of the products and packages before you pay the balance.Q3. What are your terms of delivery?A: EXW, FOB, CIF, DDU.Q4. How about your delivery time?A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time dependson the items and the quantity of your order.Q5. Can you produce according to the samples?A: Yes, we can produce by your samples or technical drawings.Q6. Do you test all your goods before delivery?A: Yes, we have 100% test before deliveryQ7: How do you make our business long-term and good relationship?A:1. We keep good quality andpetitive price to ensure our customers benefit ;2.rely do business and make friends with them, no matter where theye from. zamlhi7l50OG

Get Price